Mirsee's MH3 Redefines Hazmat Response with Precision Teleoperation and Extended Runtime

Robot Details

MH3 • Mirsee RoboticsPublished

January 23, 2026

Reading Time

3 min read

Author

Origin Of Bots Editorial Team

Remote Work Gets a Hardware Upgrade

Mirsee Robotics has unveiled its third-generation humanoid platform, the MH3, positioning the 75-kilogram machine as a transformative solution for operations too dangerous or demanding for human workers. Designed and manufactured in Cambridge, Ontario, the MH3 combines bipedal locomotion with dual-arm dexterity to handle precision tasks in hazardous environments, from remote contamination cleanup to infrastructure inspection. The platform's 10-hour battery runtime and wireless charging capability enable extended operational sessions without requiring frequent swaps, addressing a critical bottleneck in field deployment scenarios where downtime translates directly to mission delays.

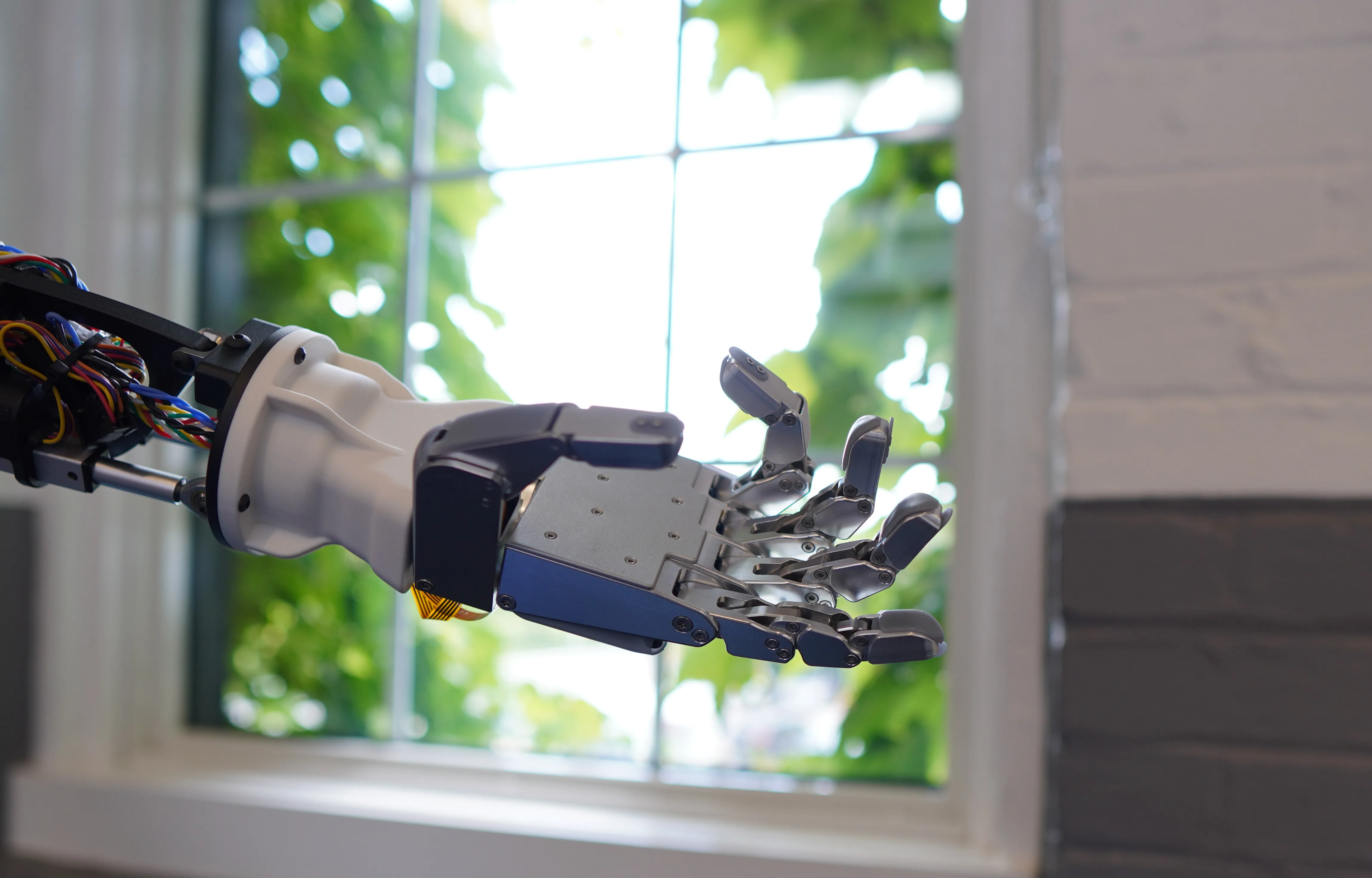

Dexterity Meets Tactical Presence

The MH3's engineering philosophy prioritizes human-like interaction over raw power, equipping the robot with 31 degrees of freedom distributed across dual arms capable of exerting up to 30 kilograms of force per limb. Each hand features six independent degrees of freedom, enabling the robot to manipulate tools, operate equipment, and handle delicate instruments with precision comparable to skilled technicians. This architecture proves especially valuable in scenarios requiring tool switching, component assembly, or instrument calibration where clumsy or imprecise movements could compromise mission success or create secondary hazards.

Sensing the Unseen

The MH3's perception stack represents a significant technical leap, integrating RGB cameras, stereo vision, LiDAR, ultrasonic sensors, and proprietary force-feedback systems throughout the arms and torso. This multi-modal sensing approach enables the robot to build real-time 3D environmental maps using simultaneous localization and mapping (SLAM) while simultaneously monitoring contact forces during manipulation tasks. The sub-100-millisecond latency between visual input and motor response ensures responsive teleoperation, critical when operators must react to unexpected obstacles or dynamic hazards in real-time.

Where MH3 Delivers Impact

Real-world deployment scenarios span industrial assembly lines, precision tool handling in manufacturing facilities, and remote operation in contaminated or radiation-affected zones where human presence poses unacceptable risk. The robot's collaborative safety features—including force limiting, collision detection, and emergency stop protocols—enable shared workspace operations where the MH3 works alongside human technicians without requiring expensive containment barriers. Service robotics applications benefit from the platform's ability to navigate tight spaces at speeds up to 3.5 kilometers per hour while maintaining stable footing on uneven terrain.

Capability Architecture Breakdown

The MH3's technical foundation enables sustained interaction across extended operational windows through strategic engineering choices. Its 170-by-50-by-40-centimeter form factor balances reach and stability, while the integrated IMU and gyroscope systems enable natural bipedal walking without constant operator correction. Force sensors embedded throughout both arms provide haptic feedback during teleoperation, allowing operators to "feel" resistance and adjust grip pressure—essential for tasks ranging from delicate instrument handling to emergency tool deployment. The ROS2-based operating system with C++ and Python APIs allows rapid integration of specialized perception algorithms or task-specific control routines, while the onboard NVIDIA computing platform processes stereo vision and LiDAR data without cloud dependency, crucial for classified or isolated environments where network connectivity cannot be guaranteed.

Versus Rivals Breakdown

| Robot | Strengths over MH3 | MH3 Advantages | Weaknesses vs. MH3 |

|---|---|---|---|

| MH2 | Previous generation baseline | 31 DoF vs. predecessor; 10-hour runtime; enhanced haptic feedback | Older sensor architecture; reduced battery capacity |

| Dex (Richtech) | Marginally faster walking speed (3.6 km/h) | Superior LiDAR-first mapping; larger payload capacity; better arm force distribution | Shorter runtime (6 hours); lighter build limits industrial durability |

| Mornine | Specialized bipedal gait optimization | MH3 offers broader industrial task flexibility; stronger arm actuation; more advanced stereo vision | Mornine focuses on speed over precision manipulation |

| MH1 | Early prototype reference point | Complete generational leap in dexterity, runtime, sensing; production-ready reliability | Obsolete platform; minimal modern capabilities |

Sources

Related Articles

Deep Robotics' DR01 Humanoid Charges Toward Mass Production

DR02 Conquers Rain, Dust with IP66 All-Weather Mastery

Chery's Mornine Redefines Retail Robotics with Real-World Dexterity and Global Expansion

Mirokaï Humanoids Enter UK Healthcare Trials to Elevate Patient Support

Learn More About This Robot

Discover detailed specifications, reviews, and comparisons for MH3.

View Robot Details →